When it comes to starting your car, numerous sensors work in unison to ensure that the engine starts smoothly and efficiently.

These sensors play crucial roles in monitoring engine conditions and ensuring that the fuel and air mixtures are optimized for combustion.

If any of these sensors fail, it may lead to your car not starting or experiencing other performance issues.

Some common sensors that can cause a car not to start include the crankshaft position sensor, camshaft sensor, mass air flow (MAF) sensor, throttle position sensor, and more.

These sensors are typically connected to essential components such as the fuel pump or the Engine Control Unit (ECU), and their failure can have a significant impact on your car’s ability to start.

Key Takeaways

- Various sensors are involved in the process of starting a car’s engine, and are vital to the smooth operation of the vehicle.

- The malfunction of critical sensors like the crankshaft position sensor or MAF sensor can cause a car not to start.

- Proper diagnosis, replacement, and maintenance of these sensors are essential for preventing engine starting issues.

Common Sensors Affecting Car Start

This section discusses the most common sensors that may cause a car not to start: camshaft position sensor, crankshaft position sensor, mass air flow sensor, and engine coolant temperature sensor.

Camshaft Position Sensor

The camshaft position sensor is responsible for detecting the position of the camshaft and sending that information to the car’s Engine Control Module (ECM).

This information helps the ECM control fuel injection and ignition timing. If the camshaft sensor is faulty or fails, it can lead to incorrect fuel and ignition timing and prevent the car from starting.

Crankshaft Position Sensor

The crankshaft position sensor is another essential component that affects the car’s starting ability. This sensor measures the position of the crankshaft, which is crucial for the engine’s combustion process.

If this sensor is malfunctioning, it can cause the ECM to miscalculate the crankshaft’s position, resulting in faulty ignition timing and preventing the engine from starting.

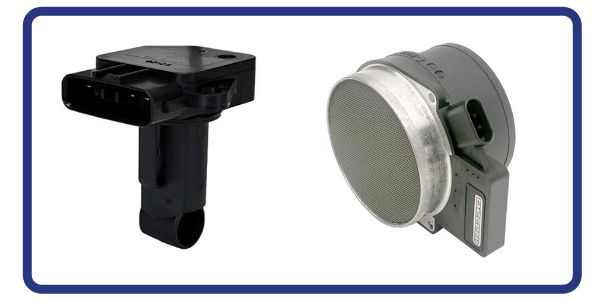

Mass Air Flow Sensor

The mass air flow sensor is responsible for measuring the amount of air entering the engine. This information allows the ECM to determine the correct air-to-fuel ratio needed for optimal combustion.

A faulty mass air flow sensor may send incorrect air flow data to the ECM, resulting in an improper fuel mixture. A car with a malfunctioning mass air flow sensor may struggle to start or exhibit other unusual symptoms.

Engine Coolant Temperature Sensor

The engine coolant temperature sensor monitors the temperature of the engine’s coolant. This information is crucial for the ECM to adjust the air-to-fuel mixture and determine the appropriate cooling fan operation.

If the engine coolant temperature sensor is faulty, it may provide incorrect temperature data to the ECM and prevent the engine from starting. A failing coolant temperature sensor may cause hard starting, poor fuel economy, and engine overheating.

Symptoms of Faulty Sensors

Engine Cranking but not Starting

Faulty sensors can lead to inadequate air-fuel mixture and incorrect ignition timing, causing the engine to crank but not start.

Typically, this could be due to a faulty crankshaft position sensor, camshaft sensor, or mass air flow sensor. When these sensors fail, the car’s Engine Control Unit (ECU) cannot accurately determine the engine’s position and ensure proper combustion.

Intermittent No Start Condition

An intermittent no start condition can be a symptom of a malfunctioning oxygen sensor or engine coolant temperature sensor.

These sensors communicate vital information to the ECU, such as the engine’s temperature and the level of oxygen in exhaust gases.

If these sensors provide incorrect data, the ECU may struggle to adjust the air-fuel mixture correctly, resulting in a sporadic inability to start the engine.

Poor Engine Performance

Poor engine performance can also stem from faulty sensors, such as the throttle position sensor or the mass air flow sensor. When these sensors malfunction, the ECU may receive incorrect input about the throttle’s position and the airflow entering the engine. This can lead to symptoms like:

- Hesitation and misfiring during acceleration

- Lack of power

- Decreased fuel efficiency

- Engine stalling

Check Engine Light

The check engine light can be triggered by a variety of factors, including faulty sensors. If a sensor like the knock sensor or crankshaft position sensor fails, it may cause the check engine light to illuminate.

In these cases, it is important to have the vehicle’s diagnostic codes read by a professional to accurately identify and address the underlying issue.

Diagnosing Sensor Problems

When trying to determine the cause of a car not starting, it is essential to examine various sensors that ensure the vehicle’s proper functioning. In this section, we delve into different methods for diagnosing sensor problems.

On-Board Diagnostics (OBD) System

The On-Board Diagnostics (OBD) system is a useful tool for diagnosing sensor issues in vehicles. By connecting an OBD scanner to the vehicle’s diagnostic port, one can retrieve diagnostic trouble codes (DTCs) related to the sensors.

These codes provide valuable information about which sensor may be causing the problem and aid technicians in the troubleshooting process.

Visual Inspection

A visual inspection of the different sensors can help identify any visible damage or abnormal wear. For instance, check the wiring and connectors of the crankshaft position sensor, camshaft sensor, and mass air flow sensor for any damages or loose connections.

In cases of a damaged or broken wiring harness, replacing the sensor may not be necessary – repairing the wiring can sometimes resolve the issue.

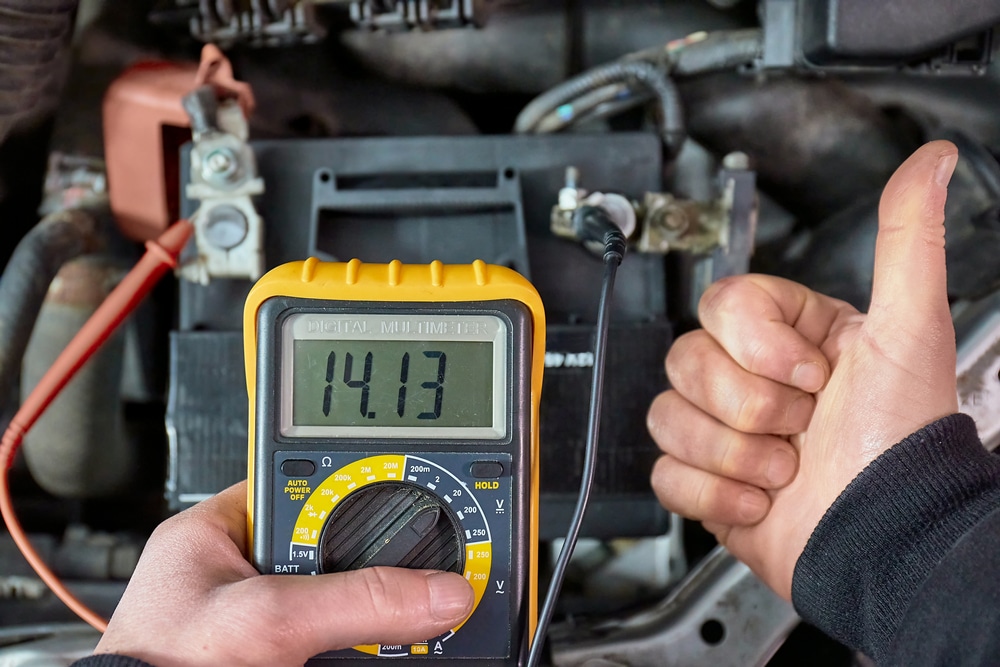

Testing Sensors with a Multimeter

A multimeter is an essential tool for diagnosing sensor problems in a vehicle. By measuring resistance or voltage as required, a technician can determine if a particular sensor is functioning within its prescribed parameters. Here are some examples of using a multimeter to test different sensors:

- Crankshaft Position Sensor (CKP): Measure the sensor’s resistance and compare it to the manufacturer’s specifications. If the resistance is out of the specified range, the sensor likely needs replacing.

- Mass Air Flow Sensor (MAF): Measure the output voltage from the MAF sensor while the engine is idling. A functioning MAF sensor should have a stable voltage output within the specified range. A fluctuating voltage or an output outside the manufacturer’s specifications can indicate a faulty sensor.

Remember to consult the vehicle’s repair manual for the correct testing procedures and specifications for each sensor. Additionally, it is crucial to adhere to safety guidelines when working with electrical components in a vehicle.

Replacing and Maintaining Sensors

Maintaining and replacing the various sensors in your vehicle is essential for keeping it running smoothly and avoiding issues with starting.

In this section, we’ll discuss the importance of following manufacturer recommendations and choosing quality replacement parts for your vehicle.

Following Manufacturer Recommendations

It’s crucial to follow the recommendations provided by the vehicle’s manufacturer when it comes to the maintenance and replacement of sensors.

Each vehicle is designed with specific sensors for optimal performance, and adhering to the manufacturer’s guidelines will ensure that these sensors stay in good working condition.

Additionally, following the recommended maintenance schedule will help you to identify and address any potential issues before they lead to further problems or damage.

- Always consult your vehicle’s owner’s manual for the recommended maintenance schedule.

- Adhere to the suggested intervals for checking, cleaning, or replacing sensors.

- Stay aware of any warning signs or symptoms indicating a possible sensor issue.

- Immediately address any issues discovered during maintenance checks to prevent further problems.

Choosing Quality Replacement Parts

When it becomes necessary to replace a sensor in your vehicle, selecting a high-quality replacement part is critical to ensure the continued optimal performance.

Not all replacement parts are created equal, and using a cheap or poorly made sensor can lead to additional complications and potential failures down the line.

To guarantee the best results, always consider the following when selecting replacement sensors:

- Look for parts from reputable manufacturers and suppliers

- Confirm that the replacement part is compatible with your specific vehicle make and model

- Avoid purchasing used parts, as their remaining lifespan may be questionable

- Consult a knowledgeable mechanic or technician if unsure about which part is needed

Conclusion

In summary, a vehicle’s ability to start is greatly influenced by the proper functioning of its various sensors. Faulty sensors can cause a car not to start and may require replacement in order for the vehicle to operate correctly.

Some of the most common sensors that can cause a car not to start include the oxygen sensor, crankshaft position sensor, mass air flow sensor, camshaft sensor, knock sensor, and throttle position sensor.

These sensors are integral to the smooth and efficient operation of the car’s engine and other systems, as they relay vital information to the engine control module. A malfunctioning sensor can result in an incorrect air-fuel mixture during the start-up phase, causing the vehicle to hesitate or fail to start altogether.

It is crucial for car owners and mechanics to understand the role of these sensors in the overall performance of the vehicle. Regular maintenance and the prompt replacement of faulty sensors can help prevent starting issues, ensuring a longer lifespan for the car and a safer driving experience.

Frequently Asked Questions

What are common symptoms of a bad crankshaft position sensor?

A bad crankshaft position sensor can cause several issues in a car. Common symptoms include intermittent stalling, poor engine performance, reduced fuel efficiency, and, in some cases, the car failing to start. The check engine light may also illuminate, indicating a need for further diagnostics.

Can a faulty fuel pressure sensor prevent a car from starting?

Yes, a faulty fuel pressure sensor can prevent a car from starting. The fuel pressure sensor monitors the fuel pressure in the system and sends this information to the engine control module (ECM). If the sensor is malfunctioning, incorrect data can be sent to the ECM, disrupting the proper fuel supply and potentially causing the car not to start or stall.

How can a failing camshaft position sensor affect starting my car?

A failing camshaft position sensor can prevent a car from starting or cause poor engine performance. The camshaft position sensor monitors the position and speed of the camshaft and sends this information to the ECM. If the sensor is faulty, the ECM may not be able to determine the correct timing for ignition and fuel injection, leading to starting difficulties or stalling.

Does a malfunctioning idle air control valve cause issues with starting the car?

A malfunctioning idle air control valve can cause starting issues with a car. The idle air control valve regulates the idle speed of the engine by controlling the amount of air going into the throttle body. If the valve is not functioning properly, the engine may not receive the correct airflow during idle conditions, which can lead to stalling or difficulties starting the car.

Can a bad mass air flow sensor cause a no-start condition?

A bad mass air flow sensor can indeed cause a no-start condition. The mass air flow sensor measures the amount of air entering the engine and sends this information to the ECM, which adjusts the fuel mixture accordingly. A faulty mass air flow sensor can send incorrect data to the ECM, causing it to adjust the fuel mixture improperly and potentially preventing the car from starting.

How does a defective engine coolant temperature sensor impact my car’s ability to start?

A defective engine coolant temperature sensor can impact a car’s ability to start by providing incorrect data to the ECM. The coolant temperature sensor monitors the temperature of the engine coolant and plays a crucial role in adjusting various engine functions for optimal performance. If the sensor malfunctions, it may send incorrect temperature data to the ECM, causing it to miscalculate the fuel-to-air ratio or ignition timing, and ultimately resulting in starting difficulties or poor engine performance.